|

Release Liners, Rubber Separator Film, Prepreg Liners & Silicone Release Liner Films

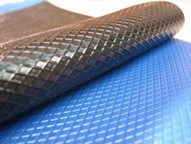

Tee Group Films has formulated a wide range of release liners, from cast embossed films to smooth films with special release additives. Our products can be used with rubber separators, Prepregs and medical tapes.

Rubber Separator Film

Tee Group Films� custom produced liners are used in calendering operations to prevent the rubber from sticking to itself once rolled up. Our Polyseal, Hylozene, and Techseal product lines are recognized around the world for their excellent quality and performance. Each product is designed to individual customer specifications and is continually perfected. Just in the past several years Tee Group Films has:

- Designed several new emboss patterns to effect the needed peel-back force required and increase our customer processing windows. (Download PDF)

- Launched a next generation High Release Film�a smooth film that recues air pockets, which helps maintain the tackiness of the material without interacting with the rubber. (Download PDF)

- Worked hand-in-hand with our customer to design a multilayered, post-consumer waste recycled product, which both addresses the rising costs of raw materials and keeps plastic out of landfills. This program has saved millions of pounds of rubber liners from being disposed of.

(Download PDF)

Product Specific Applications

Gum rubber: Tires • Belts • Hoses • Flooring • Rubber Rolls (Retread & Roofing)

Product List Product List

Tee Group Films can custom engineer products to your needs. Our Polyseal, Techseal and Hylozene product lines have been the rubber industry�s benchmark for decades.

Smooth High Release

The next step in rubber separator film • Down gauge • No pattern in your rubber

Download our Smooth Rubber Separator PDF »

Recycled Material

Address the rising costs of plastics • Cost reduction • Co-Ex with recycled material

Download our Multilayer Rubber Separator PDF »

Sustainability

Tee Group Films seeks to be a good steward of the environment and for several years has operated a comprehensive recycling program, among numerous other sustainability initiatives.

Click here for more information about our Sustainability Program »

Learn more about Tee Group Films products and view Emboss Patterns »

Prepreg Liners

Tee Group Films offers several different emboss patterns for Prepreg liners. Some of our patterns are deeply embossed to allow a vacuum to be drawn more easily during the mold forming process. We offer other patterns that are extremely shallow, which keeps the glue on the composite fresh.

We understand the expense and fragile nature of composites, so we developed the Fast Quenching process, which is unique to Tee Group Films. Our Fast Quenching process significantly reduces the elongation of film to levels unmatched in the industry�without the use of contaminate-like fillers. By reducing elongation we have decreased the degree to which film stretches under tension when applied to the Prepreg. Thus, when the film relaxes after tension is released, the stress applied to the composite is greatly reduced.

Tee Group Films works to assure our clients that their customers will always receive their composites intact.

Types of Composites Types of Composites

Thermoplastic and Thermoset Prepregs •

Fiberglass •

Carbon fiber •

Kevlar

Polyesters •

Ceramics •

Resin Systems •

Epoxy •

Phenolic •

Bismalamide

Product Specific Applications

Aerospace •

Marine •

Wind power •

Automotive •

Sporting goods

Military ballistics •

Directional fabrics •

Uni-directions fabrics

Products

Custom engineered for each client •

Smooth high release

Download our Smooth Rubber Separator PDF »

Click here to learn more about our products and view Emboss Patterns »

Silicone Release Liners

Tee Group Films has designed a specialty multilayered silicone film that features release properties on one or both sides. For enhanced release this multilayered film can be embossed. In addition, the film is extruded in a one-pass co-extruded application, which both eliminates the cost of off-line silicone coating and allows us to create highly customized films for specific purposes. These films are used as release liners in many applications, including polyurethane and polyethylene foams, medical electrodes and adhesive tape interleafs, to name a few. Tee Group Films has designed a specialty multilayered silicone film that features release properties on one or both sides. For enhanced release this multilayered film can be embossed. In addition, the film is extruded in a one-pass co-extruded application, which both eliminates the cost of off-line silicone coating and allows us to create highly customized films for specific purposes. These films are used as release liners in many applications, including polyurethane and polyethylene foams, medical electrodes and adhesive tape interleafs, to name a few.

Tee Groups Films� silicone film bridges the gap between standard polyolefin release properties and off-line silicone coated films.

Various Materials our Silicone Liners Release from: Various Materials our Silicone Liners Release from:

- Polyurethane foams

- Polyethylene foams

- Non-aggressive pressure sensitive tapes

- Fiberglass

- Plastics

Major Advantage

Product Specific Applications

Medical patches •

Automotive dashes •

Tapes •

Release liners for foams

Roofing membranes

Product List, per Customer Specifications

Custom engineered for each client

Single layer or multilayer

- Up to 5 layers

- Core and barrier materials

- Various melting points

Learn more about Tee Group Films Products and view Emboss Patterns in our Capabilities section »

|

Product List

Product List Types of Composites

Types of Composites Tee Group Films has designed a specialty multilayered silicone film that features release properties on one or both sides. For enhanced release this multilayered film can be embossed. In addition, the film is extruded in a one-pass co-extruded application, which both eliminates the cost of off-line silicone coating and allows us to create highly customized films for specific purposes. These films are used as release liners in many applications, including polyurethane and polyethylene foams, medical electrodes and adhesive tape interleafs, to name a few.

Tee Group Films has designed a specialty multilayered silicone film that features release properties on one or both sides. For enhanced release this multilayered film can be embossed. In addition, the film is extruded in a one-pass co-extruded application, which both eliminates the cost of off-line silicone coating and allows us to create highly customized films for specific purposes. These films are used as release liners in many applications, including polyurethane and polyethylene foams, medical electrodes and adhesive tape interleafs, to name a few. Various Materials our Silicone Liners Release from:

Various Materials our Silicone Liners Release from: